Content

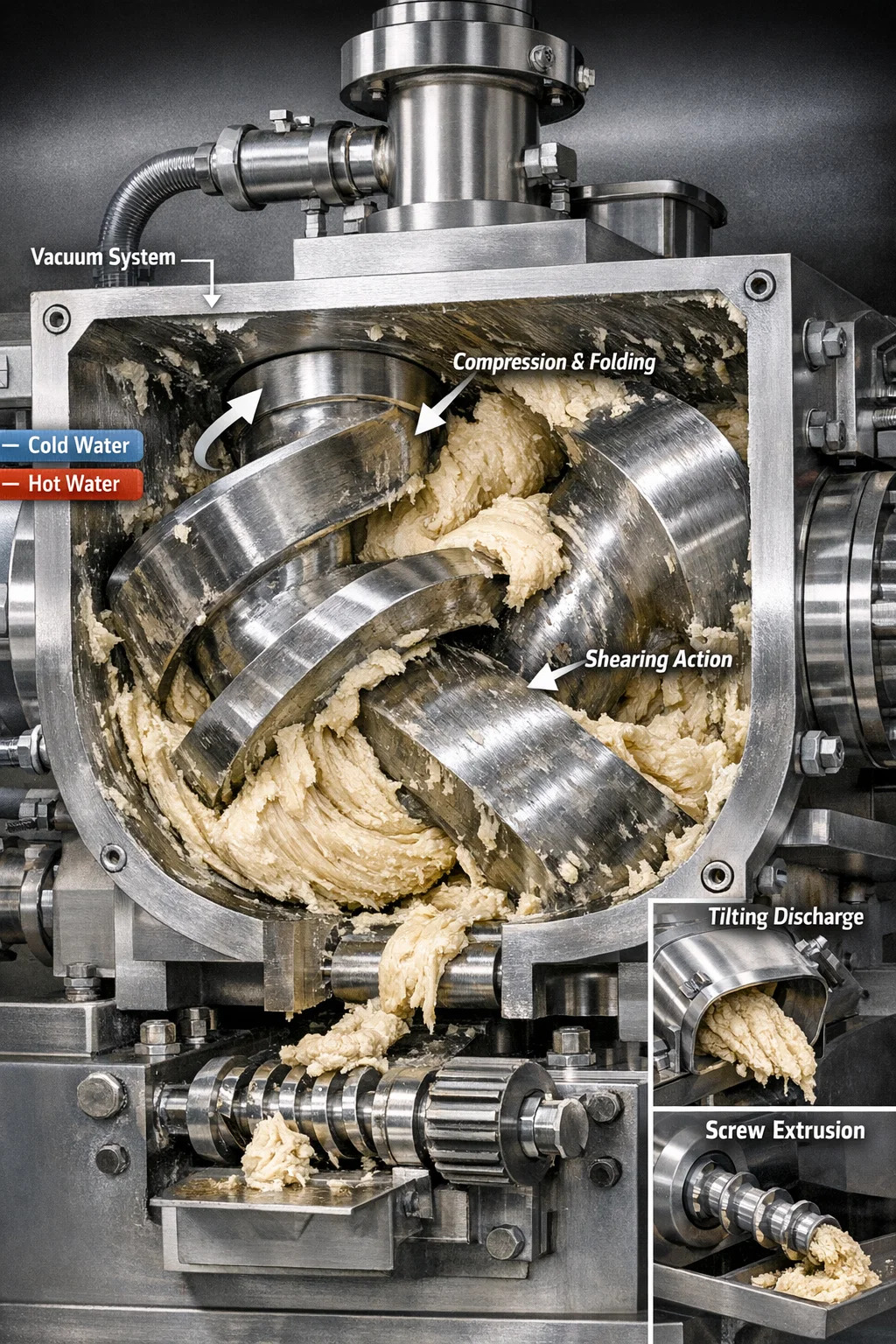

A kneader works on the same principle as kneading dough at home, but it uses immense mechanical force and sophisticated metal structures. It's not just simple "stirring," but rather processes extremely viscous materials that ordinary spoons can't handle through repeated "kneading, squeezing, pulling, and tearing."

Here's a detailed description of the kneader's operation:

1. The core "double paddle" system

The kneader's chamber usually contains a pair of metal paddles shaped like a "Z" or a fish tail.

Opposite rotation: These two paddles don't rotate in the same direction, but rather face each other and rotate in opposite directions, or rotate at different speeds.

Mutual "leverage": This design ensures that there are no dead spots in the material within the chamber; no matter how viscous the material is, it will be forcibly drawn into the gap between the paddles.

2. Powerful "compression" and "folding"

When the material is drawn between the two paddles or pushed against the chamber wall:

Compression: The immense mechanical force compresses the material tightly together, forcing incompatible components to fuse under pressure.

Folding: As the paddles rotate, the material is repeatedly turned and folded. Like kneading dough, the outer layers are folded into the inner layers, and the bottom is brought to the surface.

3. Efficient "shearing" action

This is the most crucial aspect of the kneader.

Tearing effect: Because the gap between the paddles and between the paddles and the chamber wall is very small, the material experiences a strong "tearing" force (professionally called shear force) when passing through these narrow gaps.

Breaking down lumps: This force completely breaks down any undissolved lumps or powder clumps in the material, making the entire mixture incredibly smooth and uniform.

4. Simultaneous mixing and "processing"

While working, the kneader often performs other operations simultaneously:

Temperature control: The machine's "belly" (the chamber) is usually double-walled, allowing hot or cold water to circulate between the layers. This allows for heating (to soften the material for easier kneading) or cooling (to prevent overheating and spoilage) as needed.

Vacuum extraction: If there are air bubbles in the material, the kneader can also remove the air in a sealed state, resulting in a more solid product without voids.

5. Final Separation and Discharge

Once the material is kneaded evenly and smoothly:

Tilting and Pouring: Some kneaders tilt the entire machine to pour out the kneaded "dough."

Screw Extrusion: Another method involves a long screw at the bottom, similar to a meat grinder, which directly extrudes the kneaded material in a strip-like form, like squeezing toothpaste.

English

English русский

русский Español

Español عربى

عربى